How to Avoid Unplanned DOT Inspections

Random roadside inspections aren’t so “random” after all, according to Mike Yonka, Director of Safety Services for Transportation at Sentry Insurance.

In an interview with FleetOwner, the former truck driver, fleet safety director, and human resources director shared, “Drivers don’t understand that every time you are getting inspected or there’s a violation, depending on what category it is, it drives up your score.”

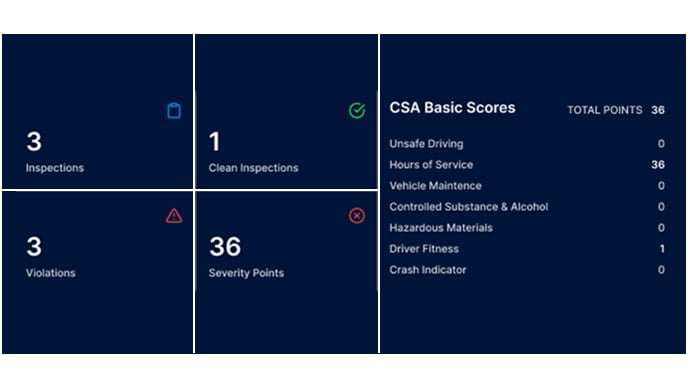

What score is he talking about? It’s often referred to as the ISS, which is the Federal Motor Carrier Safety Administration’s Inspection Selection System. Safety inspectors use it as a guide when selecting which commercial motor vehicles (CMVs) to inspect.

Based on carriers’ safety performance data, ISS scores are based on crash history, inspection history, driver history, and safety management experience.

ISS values are lumped into three different categories:

- Inspect (inspection warranted); scores between 75 and 100

- Optional (could be worth a look); scores between 50 and 74

- Pass (no inspection required); scores between one and 49

The lower your score, the less likely you are to face an unplanned inspection. On the other hand, if you’ve earned a score of 75 or above, you should expect to face one sooner rather than later. “Inspectors already know by looking at the profile of the carrier that they have an issue with inspections and vehicle maintenance,” said Yonka.

Informing Your Fleet Can Save Your Score

If you’re a safety manager, terminal manager, or hold any other influential position at your company, the responsibility of preparing your fleet for inspections weighs heavily on your shoulders. And if you’re not sharing your company’s ISS information with your drivers, you’re missing out on a key component of preventing future violations.

Openly discussing out-of-service violation numbers and ISS scores with drivers can help them understand why they have been flagged and are being inspected more often. In addition, keeping up on regular preventative maintenance (PM), as well as reminding drivers to perform quality pre- and post-trip inspections goes a long way.

The Payoff of Preventive Vehicle Maintenance

Kevin Pfost, technical service coordinator for Bendix Commercial Vehicle Systems, firmly believes in the power of conducting PMs regularly to avoid issues during roadside inspections.

He shared with FleetOwner that both technicians and drivers can measure strokes on drum brakes and ensure slack adjusters are all positioned at the same angle.

This is also a bigger problem than you may think. According to the results of the 2024 Roadcheck, brake systems were the top violation in North America, accounting for 25% of all vehicle out-of-service conditions.

Enforcement Season is Here — Are You Ready?

If an officer is looking at these wheel-end components, they’re performing a Level I inspection, which means they’re physically crawling underneath the cab and looking at the slack adjusters and the inside of the brake drums. At this point, any hope of hiding something from the officer is most likely gone.

Not only are bad brakes an inspection violation, but they’re also dangerous! It’s crucial to bring any truck with brake issues in for maintenance immediately, especially before it’s rolling down the road at full speed without any way to stop it.

The Power of Pre- & Post-Trip Inspections

The point of conducting pre-trip inspections is to catch minor quick fixes that could have a major impact on the results of an official inspection. Simple things like checking the headlights, the horn, and whether a fire extinguisher is in the truck should be done every time a driver is about to hit the road.

Encouraging drivers to change their mindset about these pre- and post-trip inspections can make a real difference. If they have safety at the top of their priorities, they’re going to look at things differently while on the job.

Looking out for themselves, co-workers who may use the same truck, and other drivers on the road should be their focus, and these inspections play a definitive role in that.

Get Your FREE DOT Audit Survival Guide Today!

Having proper documentation is also a crucial component of the inspection process, Yonka indicated. Drivers should be able to show law enforcement officers the steps that they followed during their pre-trip inspections.

“If there is a severe accident and you are going into court, they are going to ask from an insurance perspective what you did,” Yonka said. “Do you have a process? Did you follow a certain way of handling those inspections? Did you do your pre-trip inspection and make sure everything was good before you hit the road?”

Yonka often encourages carriers to train drivers on their processes, since high out-of-service violations and ISS scores can cause insurance premiums to skyrocket. And when drivers find a better way to conduct their inspections, carriers should take note and always listen to driver feedback. They’re the best source of on-the-job information.

Prioritize Your Fleet’s Safety with the Right Partner

“My comment to drivers is whenever you are driving, you have to think of it as your family in that car in front of you.” Yonka urged. Putting things into perspective like this can often remind drivers how dangerous their jobs can be.

The last thing you, as a carrier, want to deal with is an accident — or worse — a lawsuit. Nuclear verdicts are taking the industry by storm (not in a good way) and becoming the detrimental fate of countless transport companies.

The above advice can help improve your fleet’s safety and success, even if you are entangled in litigation. Having a compliance partner also goes a long way in ensuring you’re following all DOT regulations.

Even if you’ve failed an inspection or safety audit, it’s not too late to get back on track. Foley’s experts offer reliable audit support to help you restore your safety rating and avoid future compliance issues. We also provide ongoing MVR Monitoring to keep track of your fleet’s driving habits, which can help save your company if you ever find yourself in a courtroom.

Talk with a DOT compliance specialist today or fill out the form below to get started.

Related Articles

5 Pro Tips for Managing Random DOT Drug Testing

Avoid These Top Inspection Violations

Unannounced CVSA Brake Inspection Results Are In

.png)